Screw Air Compressor Manufacturer | Fix Speed Screw Air Compressor

Energy Saving-the Conserve Way

A Screw Air Compressor is a highly efficient, rotary-type air compressor that uses twin helical screws (rotors) to compress air. It is widely used in industries requiring continuous, high-volume compressed air with low maintenance and energy efficiency.

How Does a Screw Air Compressor Work?

- Air Intake: Ambient air is drawn into the compressor through an intake filter.

- Compression: The twin rotors (male and female screws) rotate in opposite directions, trapping and compressing the air between them.

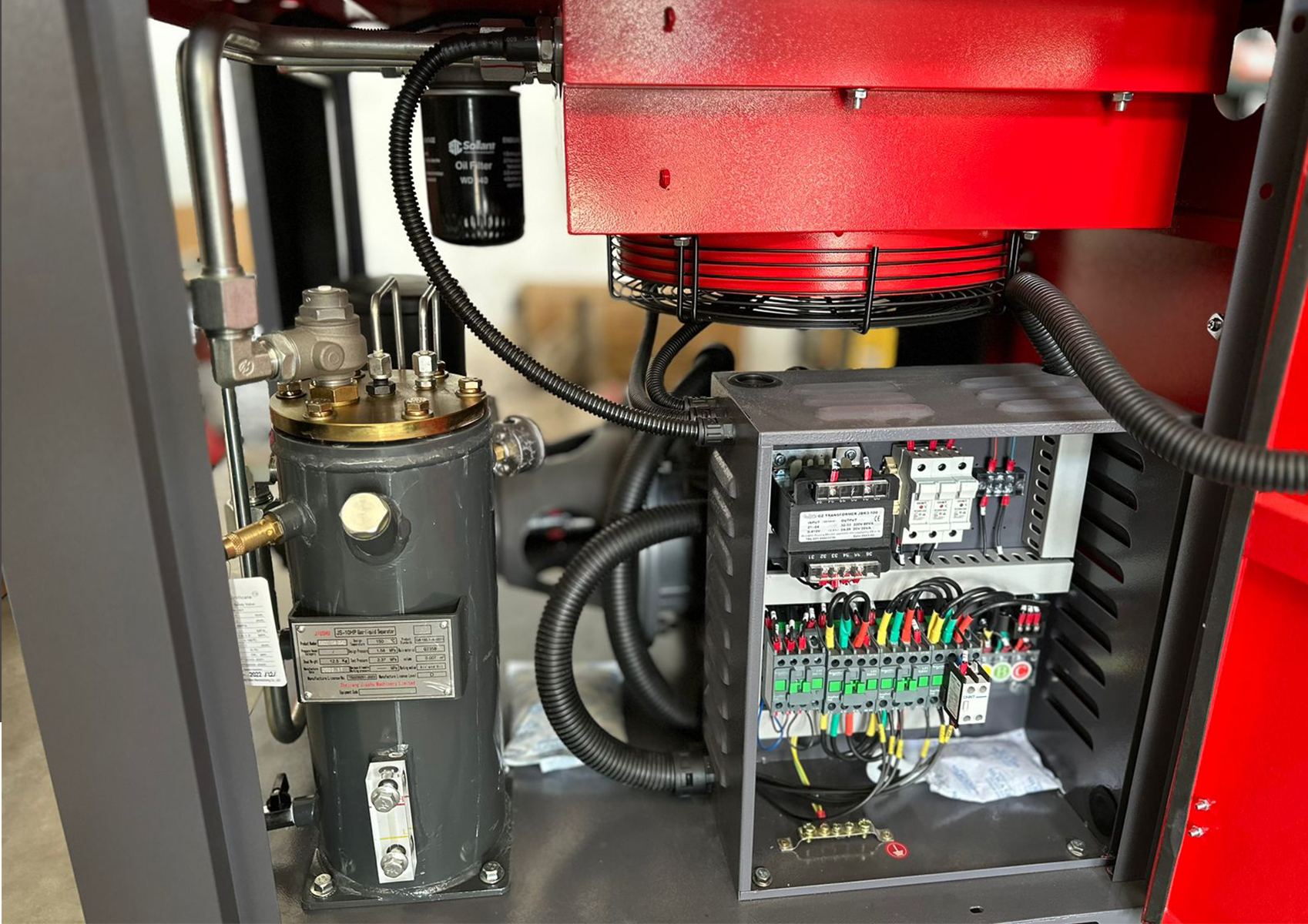

- Oil Injection (If Oil-Injected Type): Oil is injected to lubricate, cool, and seal the compression chamber.

- Air-Oil Separation: Compressed air passes through a separator to remove oil (in oil-injected models).

- Discharge: Clean, compressed air is delivered to the storage tank or directly to applications.

Benefits of Screw Air Compressors

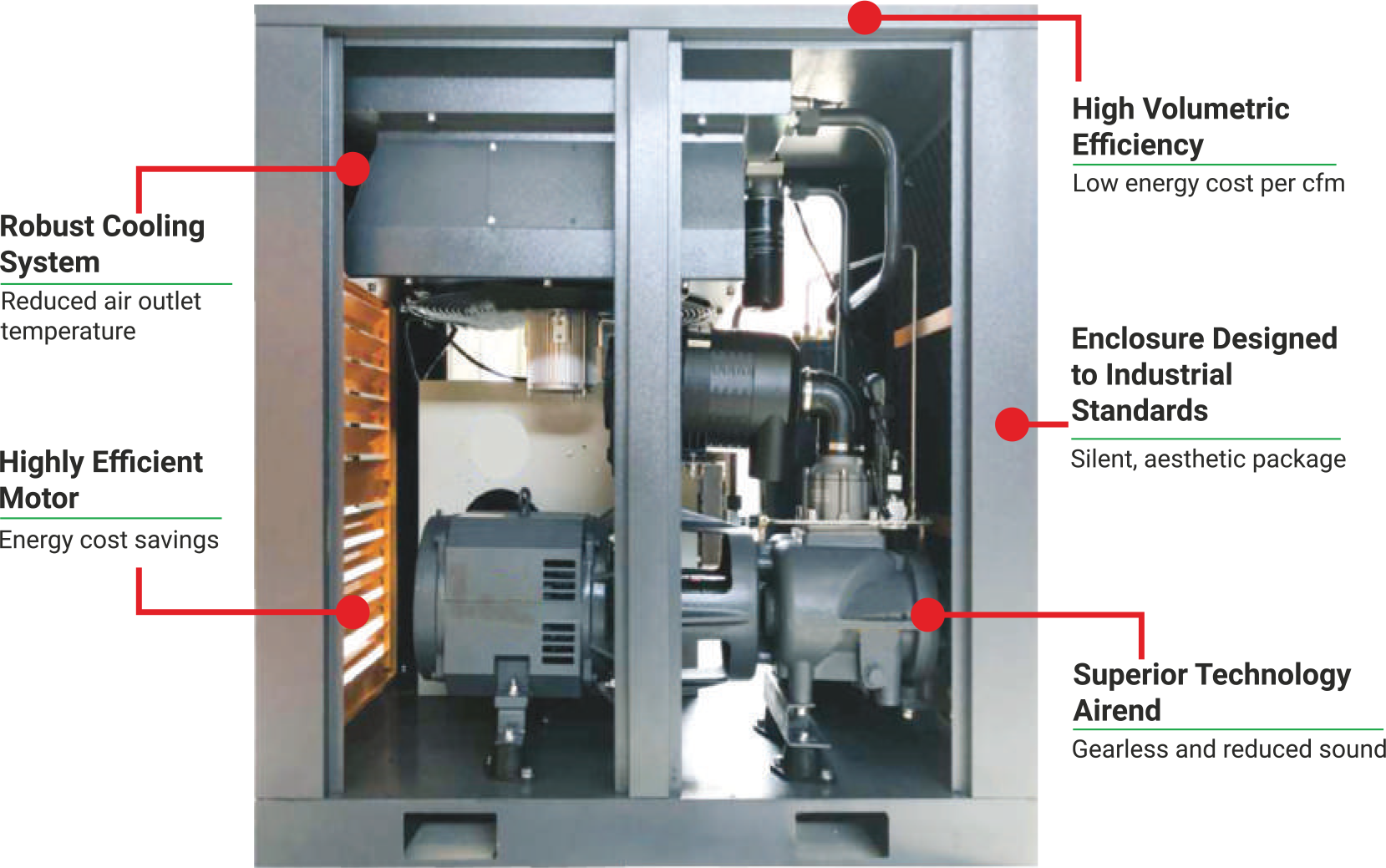

✔ Energy Efficient – Consumes less power compared to piston compressors.

✔ Continuous Operation – Ideal for 24/7 industrial use with minimal downtime.

✔ Low Maintenance – Fewer moving parts reduce wear and tear.

✔ Quiet Operation – Lower noise levels than reciprocating compressors.

✔ High Air Quality – Oil-free models provide contaminant-free air for sensitive industries.

✔ Compact Design – Saves space in industrial setups.

Industries Using Screw Air Compressors

- ManufacturingFor pneumatic tools, automation, and assembly lines.

- Food & Beverage – Oil-free compressors ensure clean air for packaging and processing.

- Pharmaceuticals– Used in sterile environments for drug manufacturing.

- Textiles– Powers spinning, weaving, and dyeing machines.

- Automotive– For painting, sandblasting, and tire inflation.

- Construction– Operates heavy machinery and pneumatic drills.

- Mining & Oil & Gas– Provides reliable air supply in harsh environments.

By understanding the working principle, benefits, and industrial applications of screw air compressorsscrew air compressors, businesses can choose the right model for their needs. Leading screw air compressor manufacturers provide customized solutions for various sectors, ensuring durability and performance.

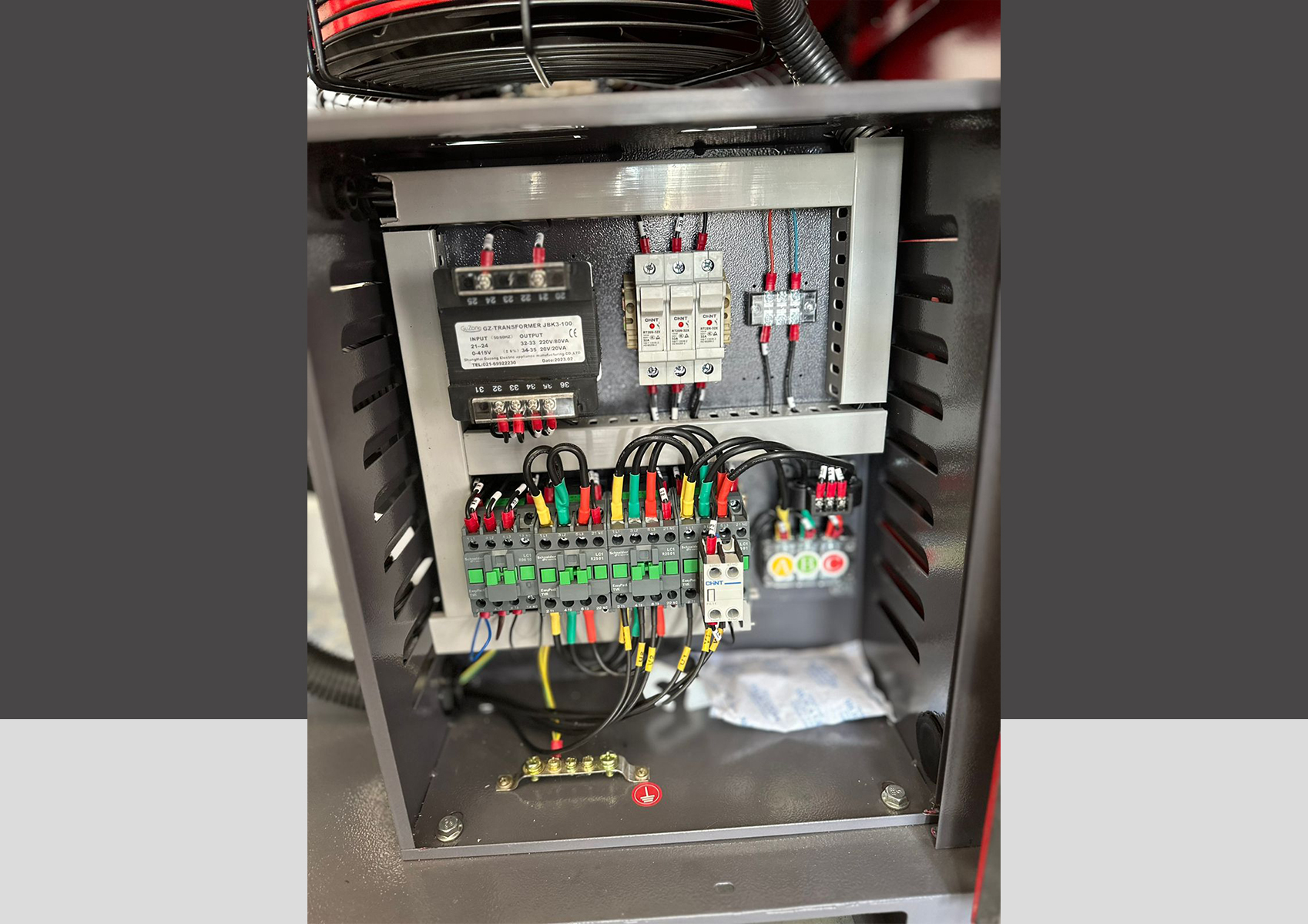

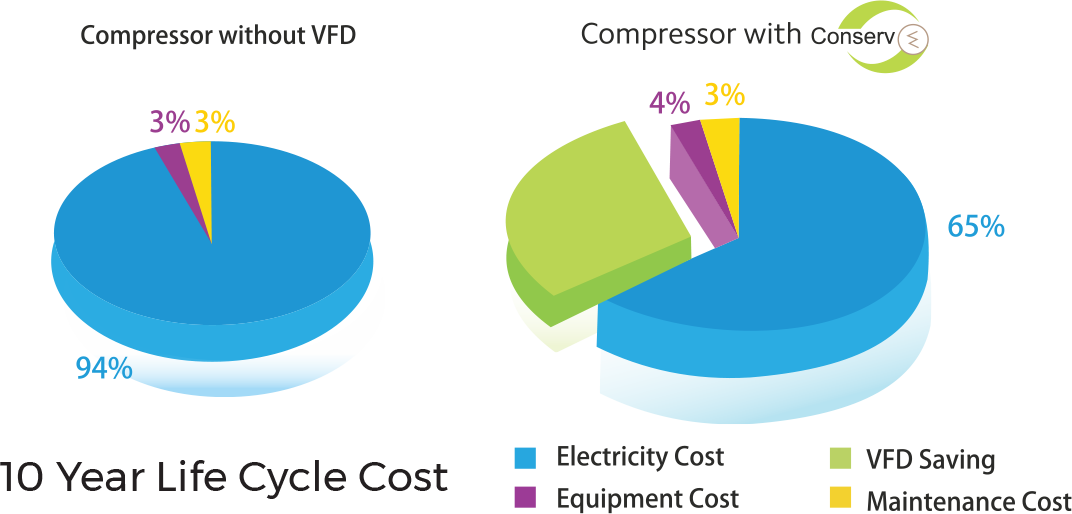

Screw Air Compressor Manufacturer In-Built RAS COMPRESSOR Variable Frequency Drives (VFD)

Matches compressor output with demand by varying motor speed. The power consumption reduces in line with the reduction in demand. Helps in eliminating the frequent load-unload cycle & also the wasted power from the energy bill.

A fixed speed compressor operates on a load unload band of at least 10 psi around the working pressure whereas with RAS COMPRESSOR VFD, compressor can be operated within a band of 2 psi.

Since the compressor is not operated under higher than working pressure requirements, there is substantial energy saving. For every 2 psi reduction in operating pressure. there is 1% power saving.

In a fixed speed compressor with Star-Delta starter, starting current is as high as three times the full load current (FLC). With RAS COMPRESSOR VFD, starting current is less than FLC. This helps to avoid using heavy rated components like fuses, MCCB, cable size, generator rating, isolate etc.

For compressed air systems with fluctuating demand pattern, giving a fast return on investment.

Advantages :

- Electrical : Low starting current Hight efficiency Improved Power factor Reduced maximum demand.

- Mechanical : Minimum maintenance Smooth start Smooth control

Its been a while since I posted – readers will realise that my lull in posts has coincided with my move to Johannesburg and my starting a new job in engineering consulting.

Installation Guide :

- "Best Screw Air Compressor Manufacturer"

- "Industrial Rotary Screw Air Compressor"

- "Oil-Free vs Oil-Injected Screw Compressor"

- "High-Efficiency Air Compressor for Manufacturing"

- "24/7 Duty Screw Compressor for Pharma Industry"

- "Low Noise Screw Air Compressor for Workshops"